FAQ

DTF Transfers Vs UV-DTF Labels Vs Dye Sublimation?

| DTF & Color Plus DTF Transfers | UV-DTF Label | Dye Sublimation | |

| General Use | Shirts, Jackets, Bags | Bottles, Jars, Packaging Material | Poly Shirts, Hard Goods |

| Application Method | Heat & Pressure | Peel & Stick | Heat & Pressure |

| Application To | Flat items made from: Cotton, Poly/Cotton Blends, Poly, Nylon, Leather, Cardboard, Wood, etc. | Items made from: Films, Acrylic, Crystal, Plastic, Metal, Ceramics, Glass, Leather, Wood, Paper, PVC Board, etc | Light Color Poly Shirts, Glass, Mugs, and many other items made for dye sublimation. |

What Is The Price?

For full pricing see our pricingShipping Cost?

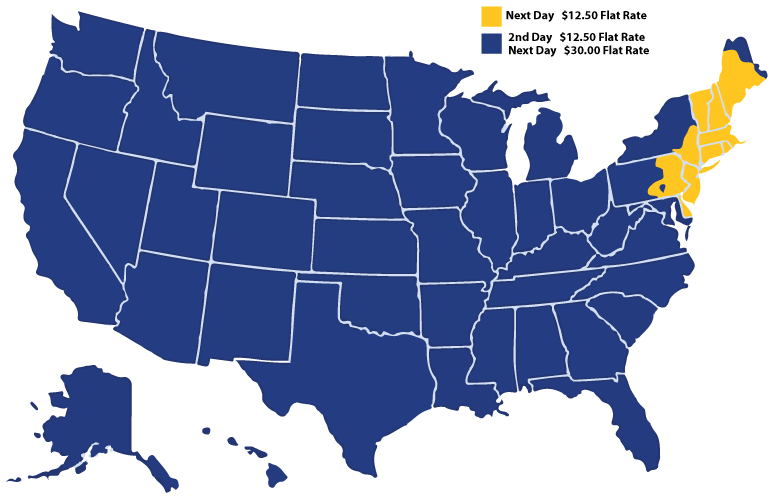

Next Day flat rate shipping is $30.00. Next Day shipping is available anywhere in the US via FedEx Next Day Service.

Tracking info will be emailed to you when transfers are shipped. At this time, we do not ship outside of the United States.

Trade Only?

We only work with companies that are active in the decoration and sale of garments, promotional products, and other printed material.DTF vs Color Plus DTF?

DTF transfers are printed with CMYK inks. Color Plus DTF transfers are printed with CMYK inks plus RGBO inks. This gives Color Plus DTF transfers a wider more accurate color range. Color Plus DTF is only available on warm-cold peel film.Warm-Cold Peel vs Instant Peel?

The advantages of warm-cold peel film are: Durable transfer, holds small detail better, applies easier to difficult materials, and the transfer itself will hold up to rough handling. The advantages of instant peel are: Faster application. In general we suggest warm-cold peel. However, instant peel is faster and will allow you to do larger jobs quickly. In the final results, there is not that much difference between the two.What happend to Hot Peel film?

Our old hot peel film is what we are now calling warm-cold peel.How To Apply Warm-Cold Peel DTF Transfers?

Transfers should be applied with a commercial grade heat press. Set the press for very firm pressure. The temperature should be set to 310 degrees fahrenheit for cotton. PrePress for 3 seconds. Position the transfer on the garment and press for 12 seconds and wait until warm or fully cold and then peel. It is not required but we do highly recommend a 2nd 12 second press using either a parchment paper or textured cloth to cover the design. For poly that may bleed, temperature can be lowered to 275 and time reduced to 10 seconds. For poly, pressure can also be reduced. You should test and adjust the time, temperature, and pressure for your equipment and materials.How To Apply Instant Peel DTF Transfers?

Transfers should be applied with a commercial grade heat press. Set the press for very firm pressure. The temperature should be set to 280 degrees fahrenheit for cotton. PrePress for 3 seconds. Position the transfer on the garment and press for 7 seconds. Peel as soon as the heat press opens. Press again for 7 to 14 seconds using either a parchment paper or textured cloth to cover the design. For poly that may bleed, temperature can be lowered to 275, and pressure can also be reduced. You should test and adjust the time, temperature, and pressure for your equipment and materials.How To Apply UV-DTF Labels?

Labels will work best when warm. If they are in a cold room or you just received them, it is a good idea to warm them before trying to peel the backing. Once warm, peel the backing slowly making sure the label design fully transfers to the clear film. Align label on item and press to stick. Press hard to make sure the label adheres well. Peel the clear film slowly making sure label has adhered to the finished item.How To Apply Dye Sublimation Transfers?

Dye Sublimation Transfers should be applied with a commercial grade heat press. The temperature should be set to 400 degrees fahrenheit with light pressure. PrePress for 3 seconds. Press transfer for 60 seconds, and quickly peel. Paper should be used between the item being pressed and the heat press to protect the heat press. For mugs and other round items, there are special heat presses or dye sublimation ovens should be used.Do UV-DTF Labels Work On Drinkware?

UV-DTF labels can be used on drinkware. However, they do not hold up well in a dishwasher. Items should be washed by hand.Do DTF Transfer Wash Well?

You will see little to no change in DTF Transfers for the first 30 washes and the transfer will continue to look good for at least 50 washes. Do not use bleach or fabric softener when washing.Available Print Sizes?

For print size see available print size and pricingFile Requirements?

Maximum file size is 100 megabytesMinimum 300dpi and Maximum 600dpi

File types: .png, .tiff, .pdf, and .ai

All designs will print as sized in the file

Transparent background

All text should be converted to curves